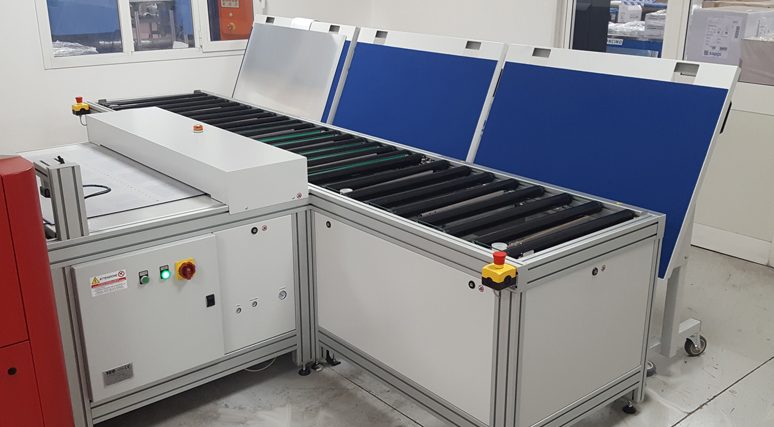

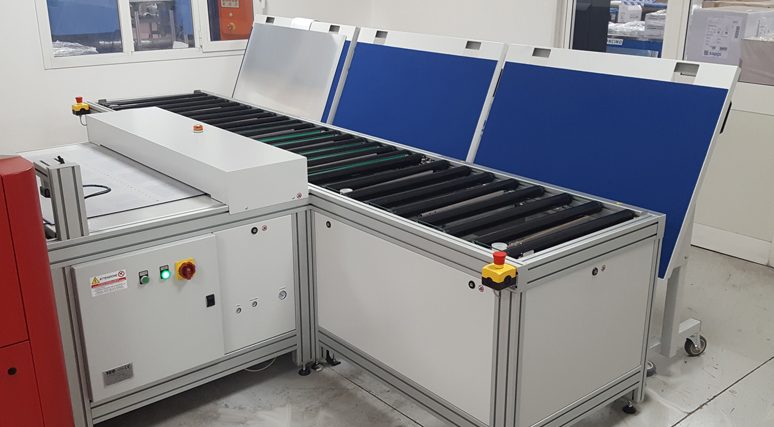

iNLINE PLATE BENDER WITH DATAMATRIX READER

The In-line plate bender is an automatic bending system specifically designed for the needs of printers using mainly Heidelberg and Komori. The plates produced are available for the presses quickly and without any manipulation. The system is placed at the exit of the developer or ctp depending on the type of plates, replacing the classic stacker. The very small size allows it to adapt to multiple requirements. The plates are identified by reading a datamatrix code engraved on the plate. Once identified they are deposited by suction cup system on appropriate trolley and sorted by job/signature .

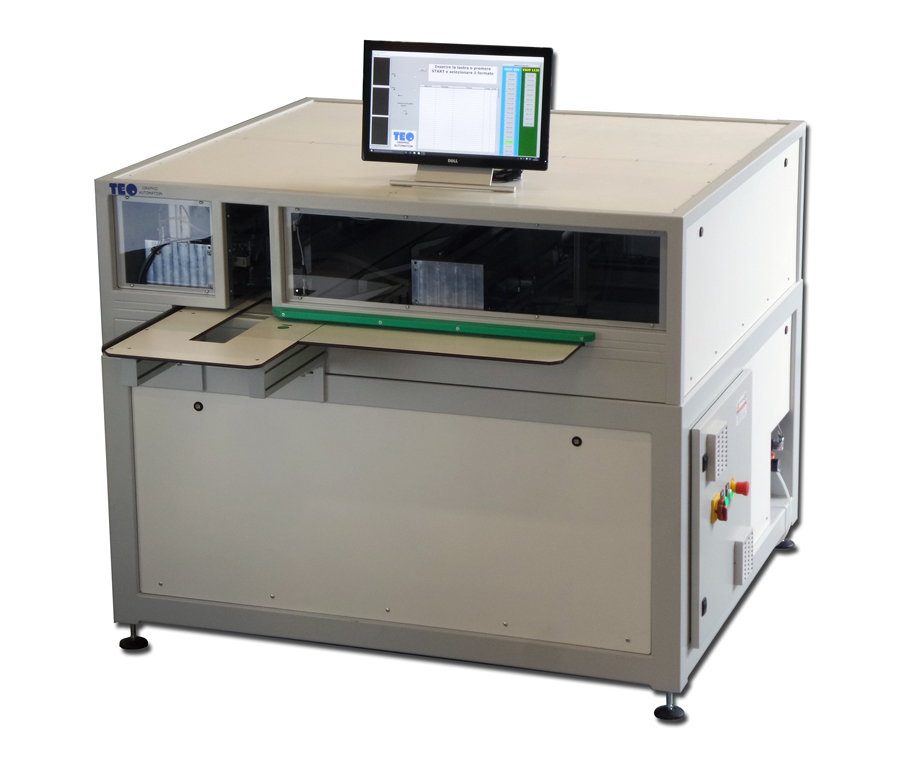

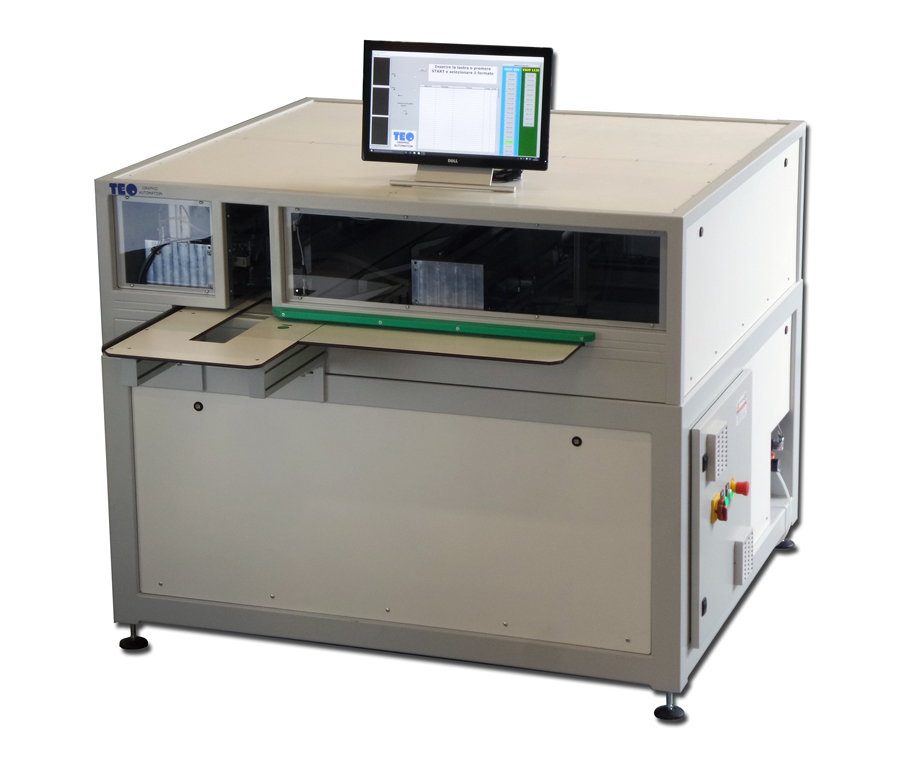

OPTICAL PLATE PUNCH AND BENDER WITH STACKER FOR HEIDELBERG/KOMORI PRINTING MACHINE

Next-generation punching and bending machine. Meets high levels of punching and bending accuracy with the introduction of optical register system via two high-resolution digital cameras. Integrated output stacker.

IN-LINE OPTICAL PLATE PUNCH A BENDER FOR NEWSPAPER

Next-generation plate bender. It meets the high levels of bending precision thanks to the introduction of optical register system using two high-resolution digital cameras. Can be inserted within a developing line or, using conveyors, can handle plates from multiple lines thanks to the ability to make more than 200 plates/hour. Available for commercial and newspaper presses. Integrated output stacker with the possibility of splitting plates at will.

MULTI-SIZE OPTICAL PLATE BENDER

Next-generation plate bender. It meets the high levels of bending accuracy by introducing optical register system via two high-resolution digital cameras. The tail bend moves by means of a motor-driven recirculating ball screw allowing bending of a variety of plate formats

OPTICAL PLATE BENDER FOR WEBOFFSET

PLATE BENDER FOR WEBOFFSET

Effettua la punzonatura in pinza e due pieghe di precisione in pinza e coda alla lastra. Le caratteristiche dimensionali della piega e della punzonatura, soddisfano le esigenze di numerosi modelli di macchine da stampa

MANUAL PLATE BENDER WITH PUNCH

Effettua la punzonatura in pinza ed una singola piega di precisione in coda alla lastra. Le caratteristiche dimensionali della piega e della punzonatura, soddisfano le esigenze di numerosi modelli di macchine da stampa